High-speed quality inspection based on optical analysis

Streamline the output inspection of moulded parts in plastics production. Incorporate our automated optical quality control system into your production process, which can check several monitored parameters, evaluate them and store them for traceability in a fraction of the time in comparison to a dedicated operator.

What will you use it for?

- Quality of plastic (e.g. overlaps, shape etc.)

- Correctness of colour shade

- Production overflows

- Overall or partial dimensions of the part

- Shape and size of holes

- Surface defects such as scratches and dents

- Inspection of sieves

- Unwanted holes in the sieves

How does it work?

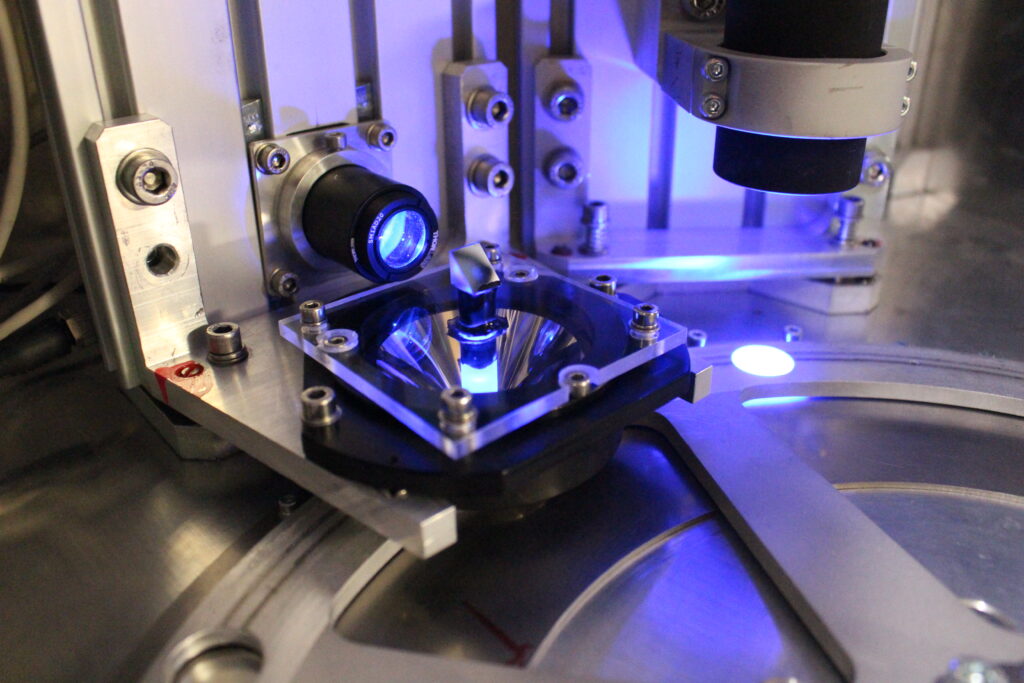

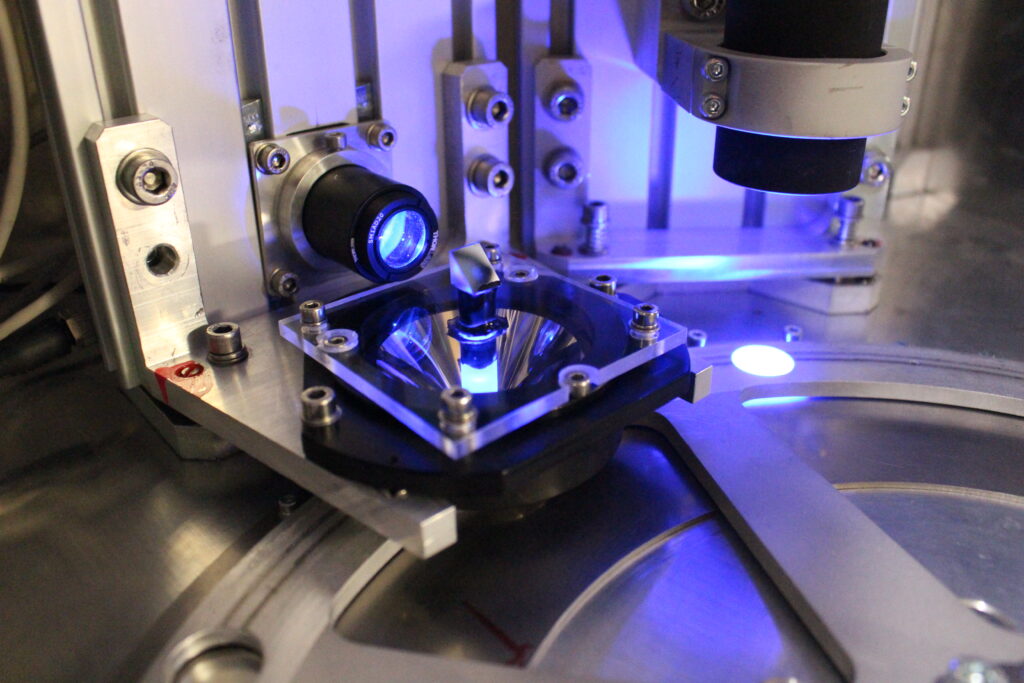

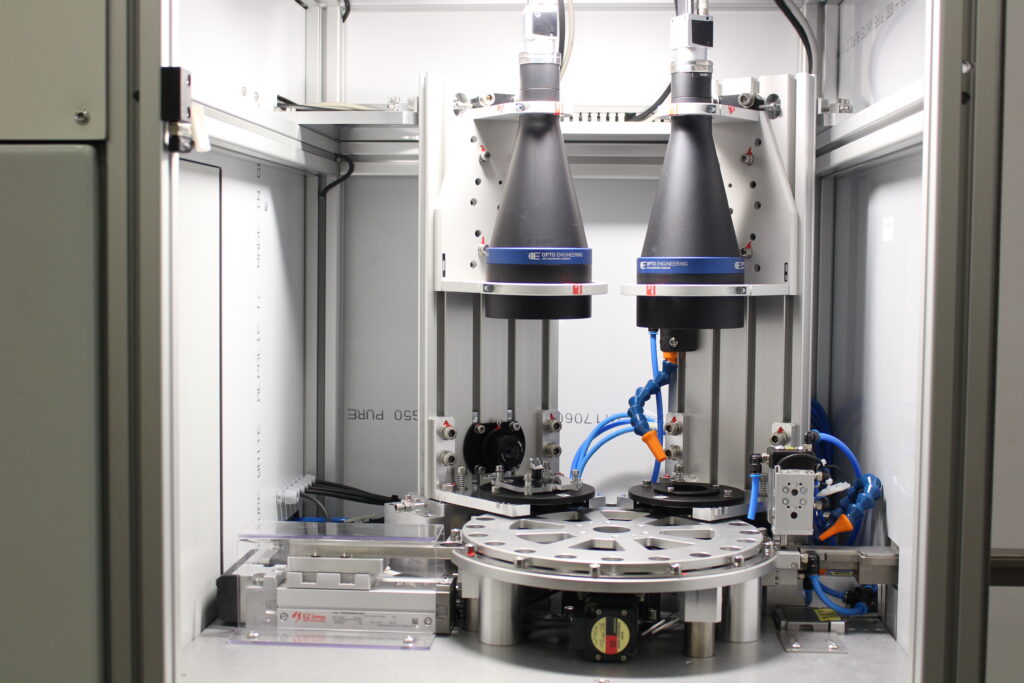

The single-purpose machine contains a tray that can hold up to tens of thousands of small plastic mouldings at a time. One by one, the mouldings are subjected to a camera inspection and within a few hundred milliseconds, we evaluate their quality based on the monitored parameters. The total cycle time for the evaluation of all parameters and part handling is up to 1 s/part. If the system does not find a defect, the part is put in the OK parts section. If any of the parameters do not fit within the specified tolerances, the part is sorted as NOK.

Key features and benefits

- Simple maintenance allowing for quick action to stop the machine in the event of an emergency shape failure

- Meets high machine speed requirements (1 pc/1 s)

- Remote access and remote service capability anywhere in the world

- Possibility to add new defect types for inspection

- Comprehensive inspection from all internal and external sides