We have been supplying our equipment to industrial companies and scientific institutions since 2008.

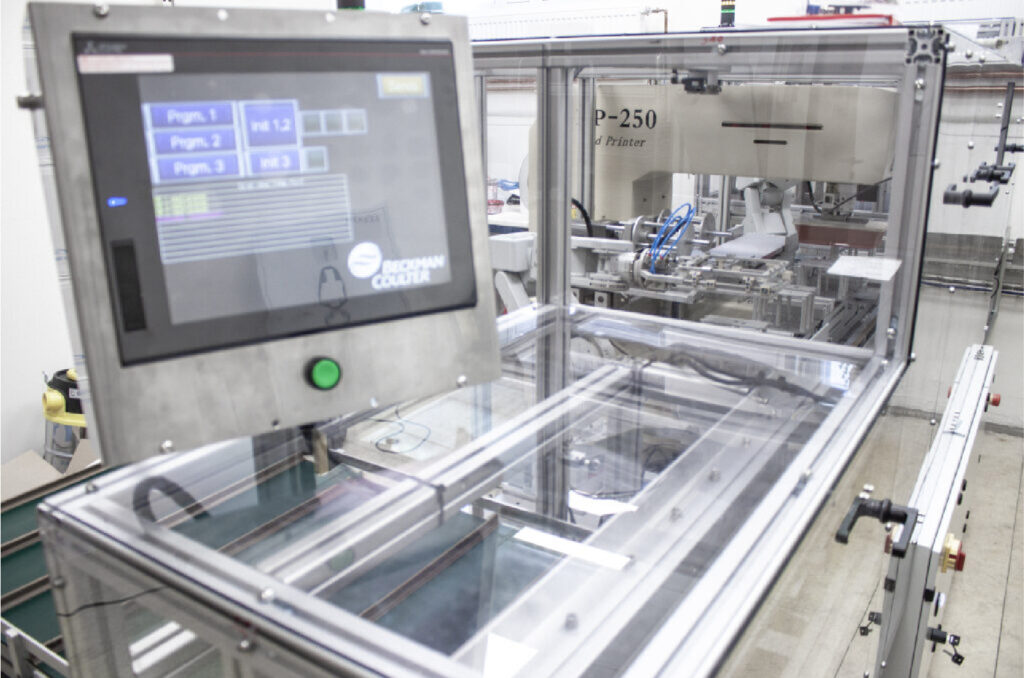

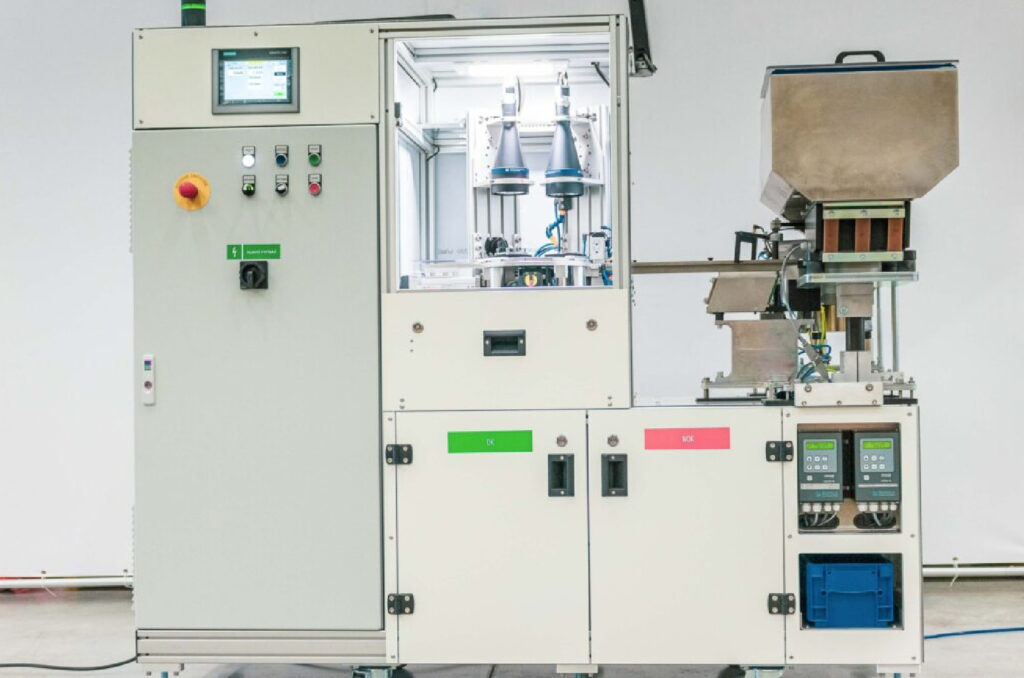

Single-purpose machine for sorting fuel filters based on optical analysis – extension to different shapes of products

Repeat delivery of a single-purpose machine with an extension to different types of the fuel filters. At the same time, the existing requirements for high machine speed (1 pcs/1 sec), loading capacity and reliability requirements for optical inspection had to be met.

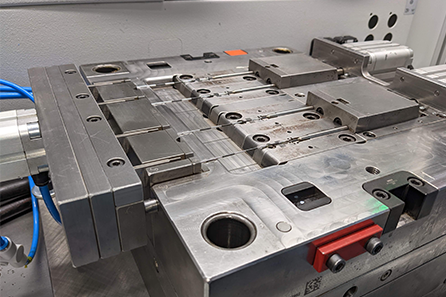

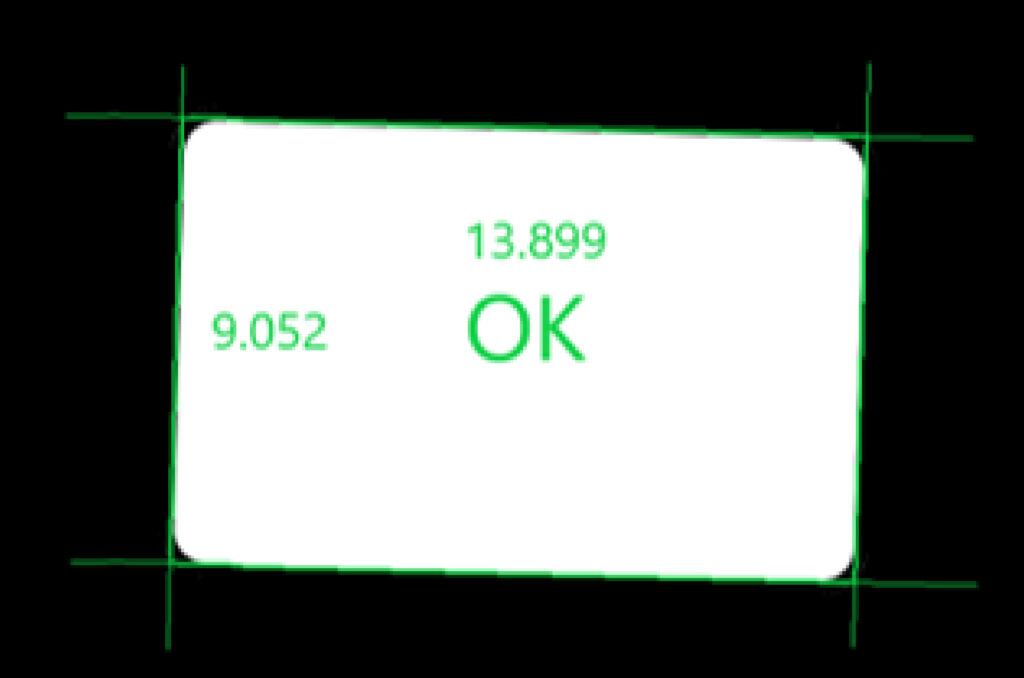

Solution for precise dimension measurement of plastic containers

Design, manufacturing and implementation of a station for the precise measurement of the dimensions of plastic containers of various shapes. The station is also tasked with sorting out the non-conforming products. The measuring station is operated by a robotic arm.

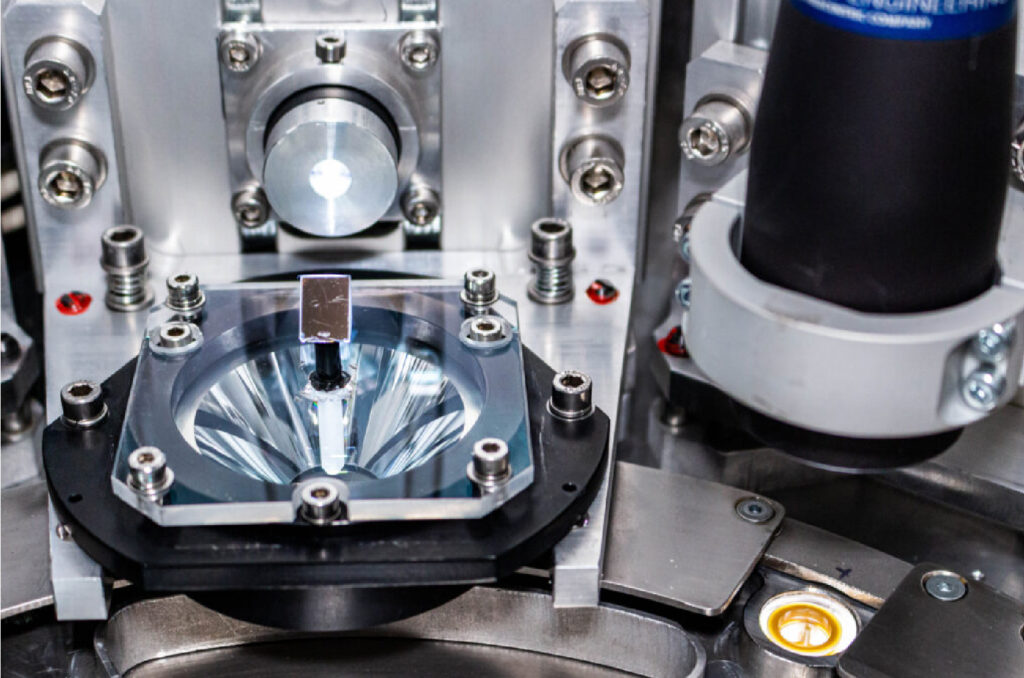

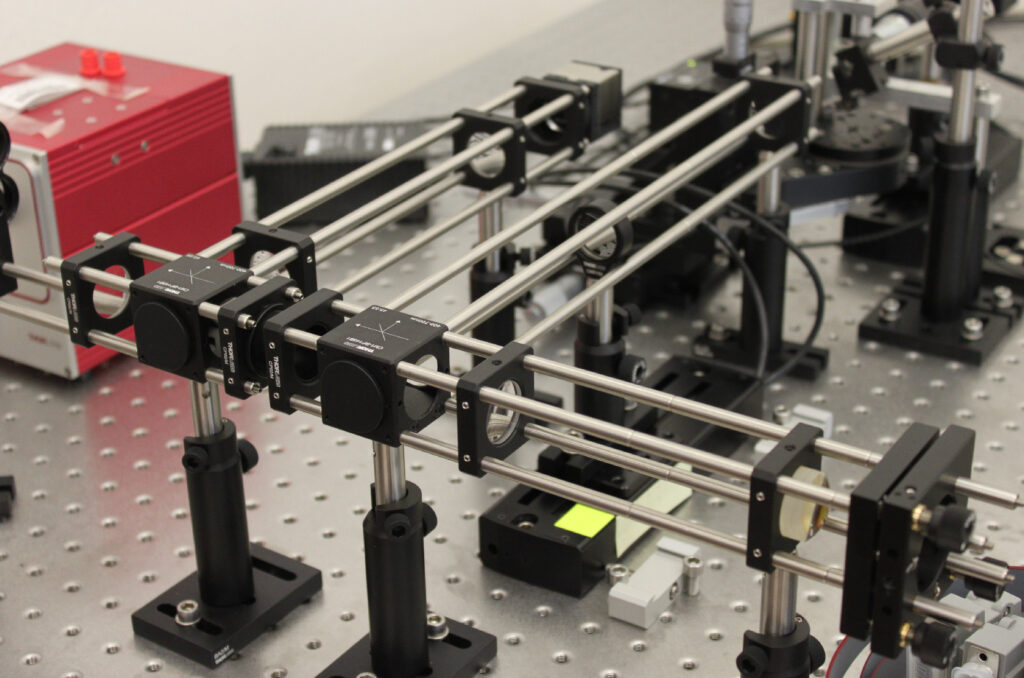

Badal optometer for the biotechnology industry

Optical table with shield and assembly consisting of an intraocular lens, camera and carriages for testing of the resolution and dioptres. The optometer scans the position and rotation of the lens. The output is an image with an automatic evaluation of the quality of the lens resolution for different object distances.

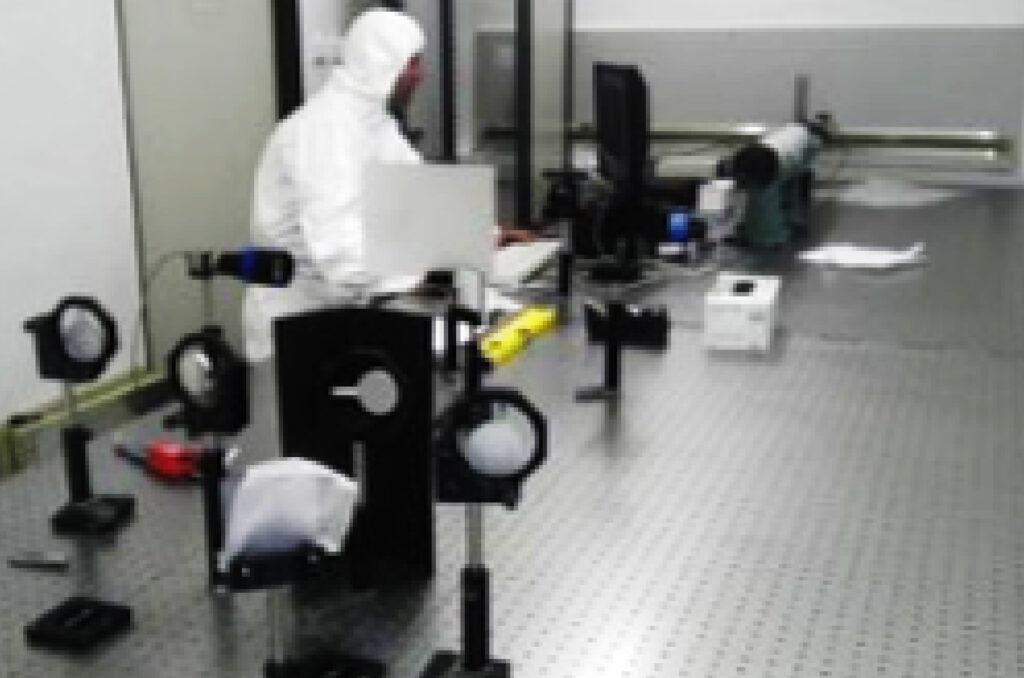

Telescope demonstrator for femtosecond laser beam transmission

For the purpose of the ELI project, a demonstrator of mirror system for beam transfer, that is placed in vacuum, was designed and fabricated. The project included the design of optics, functional verification, design of the opto-mechanics and vacuum system, optics fabrication, opto-mechanics fabrication, vacuum system fabrication, and optical testing.

White beam macroscope for beamline TOMCAT in SLS

A low magnification X-ray system with a continuous magnification change in the range of 2x - 4x was delivered to beamline TOMCAT at the Swiss Light Source synchrotron, Switzerland, at the end of 2010. The system uses a fast scientific CMOS camera and custom developed optomechanics. Changing the magnification, focusing and orientation adjustment of the camera are motorized and operate within the existing beamline control system.

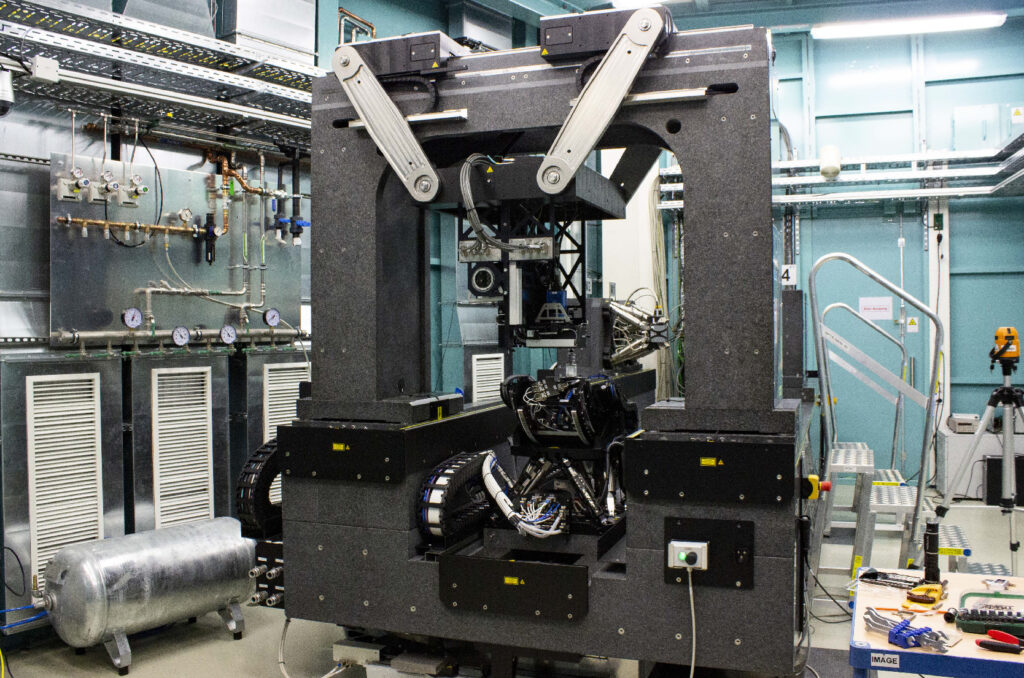

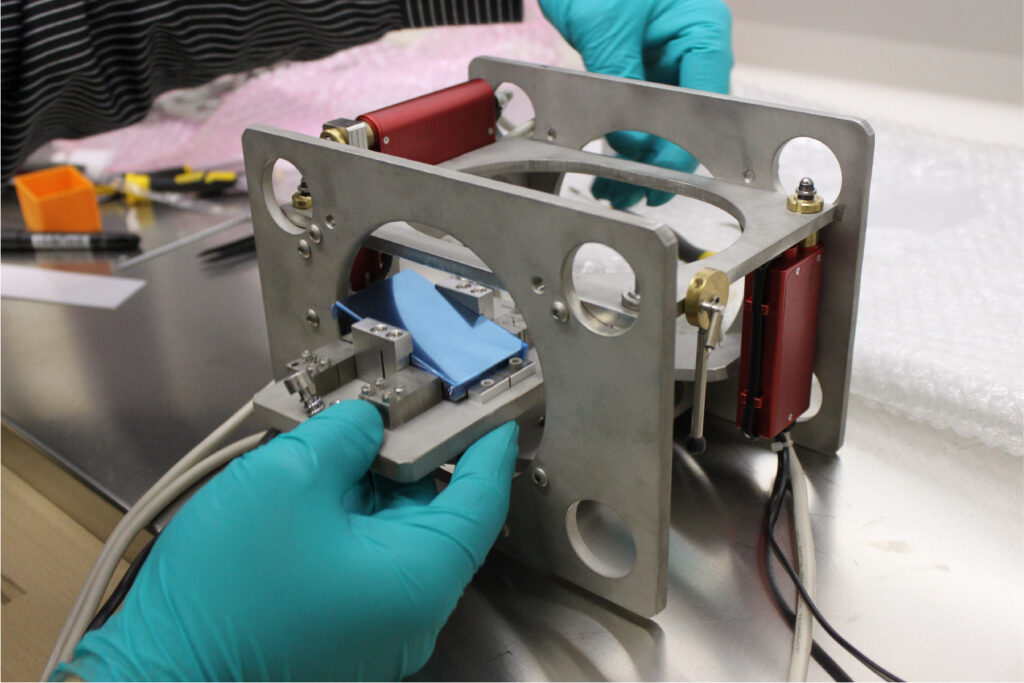

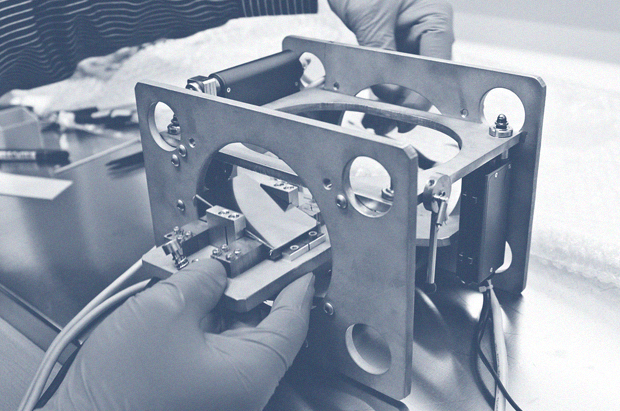

Development of Bragg magnifier mechanics for synchrotron

For the ANKA synchrotron in Karlsruhe, holders and fixtures for germanium crystals were designed and manufactured. These, in the right configuration, function as a Bragg X-ray microscope. The system was designed so that it can be easily transferred to experiments on other synchrotrons.

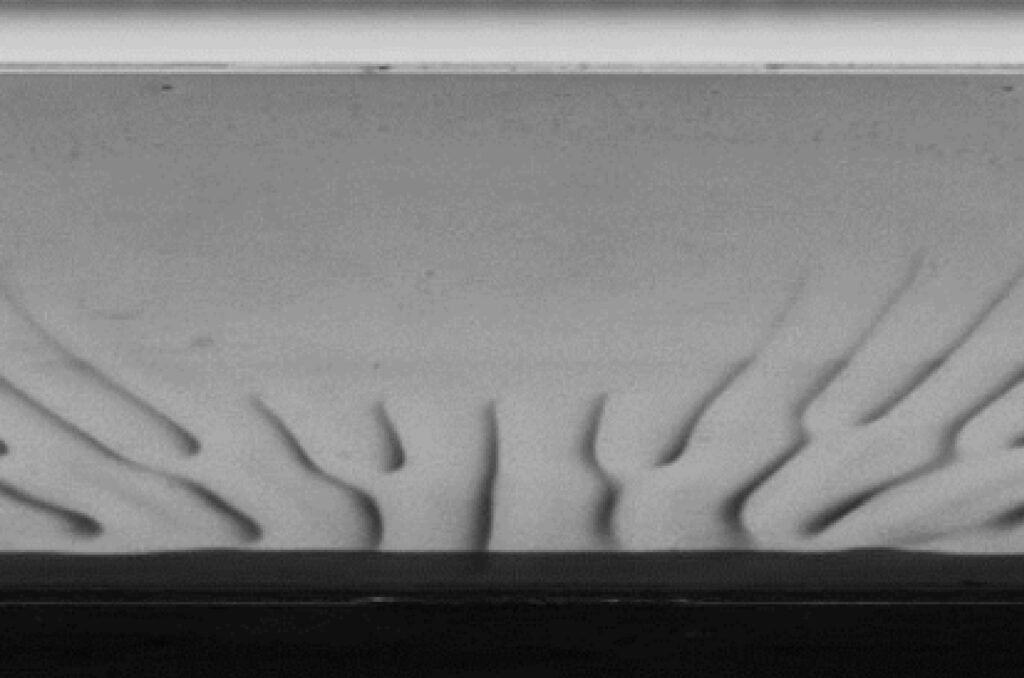

Processing of metrological data in the production of accurate honeycomb plates

Processing of metrological data and its visualization in the development and preparation of moulds for the production of precision large-scale honeycomb plates in the company 5M s.r.o. High precision of production and constant control of the mandrel shape is required in the order of 10 μm (RMS) with mandrel dimensions of about 1.5 x 1.5 m. It is necessary to take into account systematic errors in the measuring process and to perform multi-criteria optimizations.

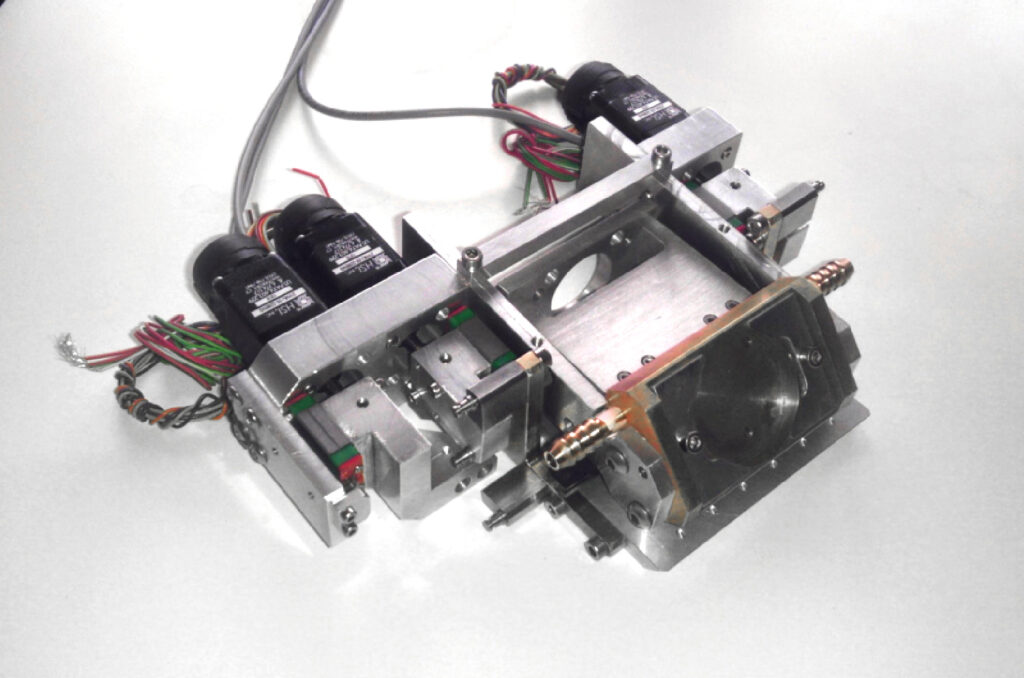

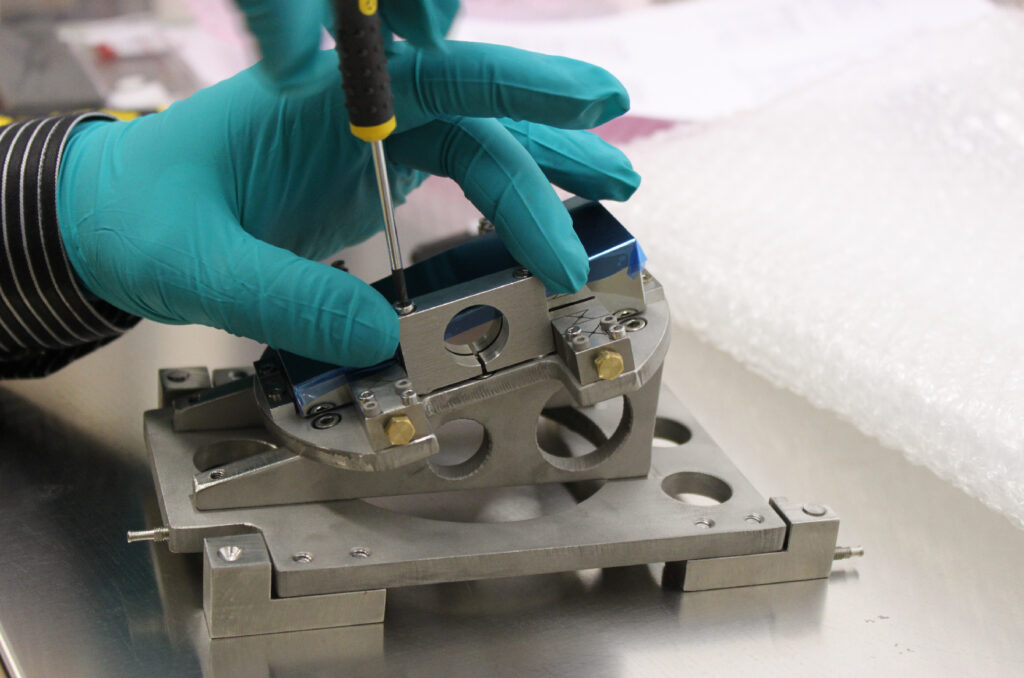

Design of mechanical parts of a scientific X-ray camera

Design of the mechanical parts of a scientific camera for soft X-ray radiation, which is detected directly on a 2000 × 2000 pixel CCD chip without a luminescent material. The camera is cooled by a Peltier cooler and a water circuit. As a part of the proposal have been also delivered the mechanics of the source electronic part.