OptiCentric 5D Bonding Station

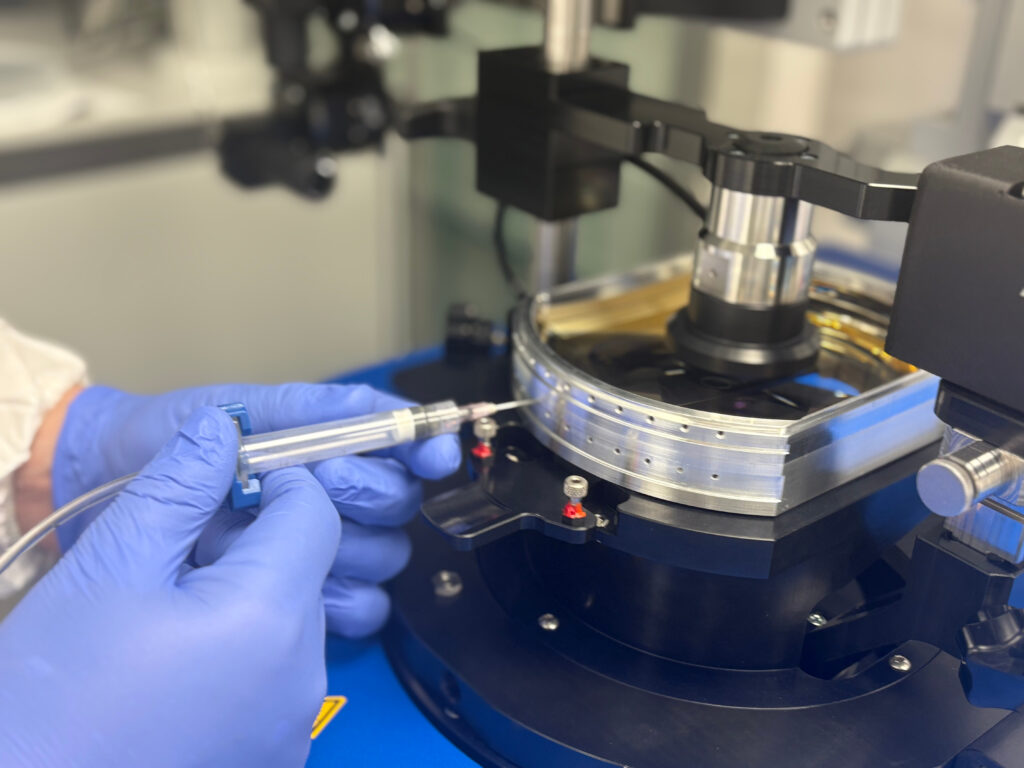

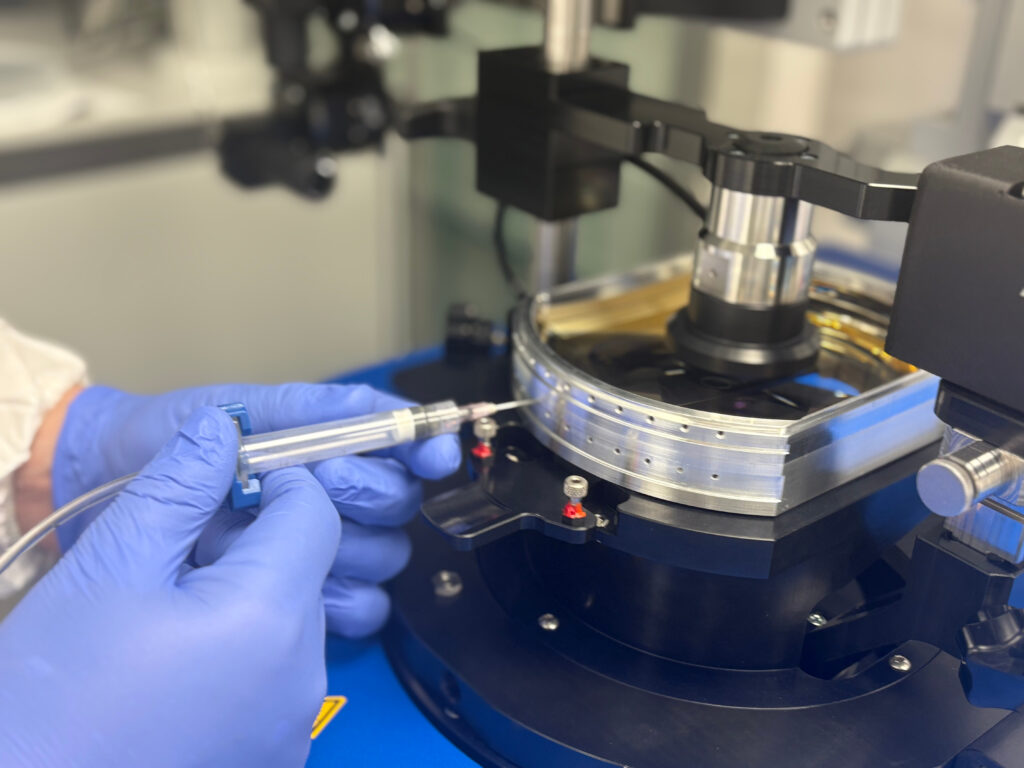

OptiCentric 5D is an advanced device from TRIOPTICS designed for precise positioning and bonding of optical components into the required mechanical assembly. This system enables precise placement of optical lenses an other elements into mechanics while compensating for imperfections, maintaining position during the adhesive curing process, and ensuring a stable and repeatable optical assembly process.

How Does OptiCentric 5D Work?

- Automatic handling and precise alignment of optical elements.

- 5-axis adjustment for precise lens positioning (<1μm arcseconds).

- Lens position stability during the adhesive curing process.

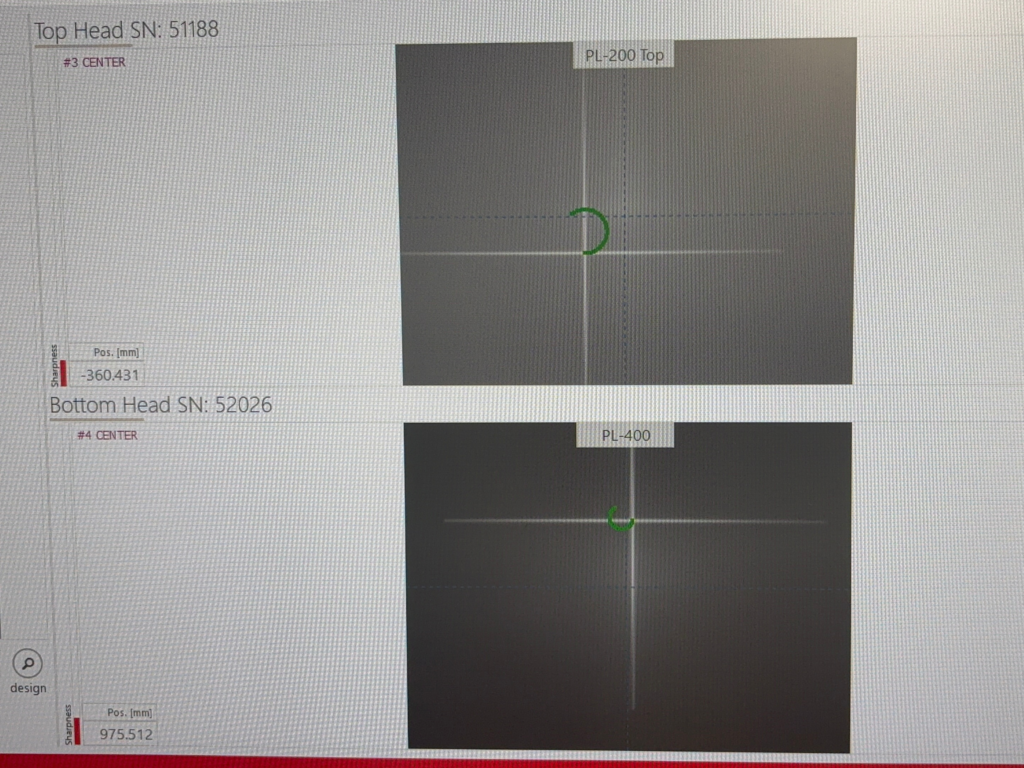

- Accurate measurement and analysis of optical components during assembly.

- Fully automated control with high repeatability of results.

- Located in a cleanroom (ISO5-ISO7) environment to minimize defects.

Key Features and Benefits

- High-precision alignment of optical components.

- Stability and repeatability of the bonding process.

- Minimal operator intervention, fully automated.

- Routinely used by our experts.

- Compatibility with various optical assemblies.

- Cleanroom environment to reduce defects.

- Online monitoring, reporting and process recording.

- Unique equipment in the Czech Republic.