Establishment of Elya Solutions s.r.o. Originally the company focused on measuring instruments, fine mechanics and software development for research institutes.

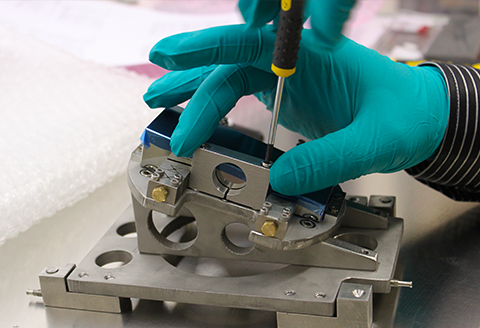

ELYA specializes in the development and production of cutting-edge optical systems for the aerospace and defense industry. We are one of the few companies in the world that can develop and produce transparent Head-Up Displays for aircraft, and our systems ensure the highest standards.

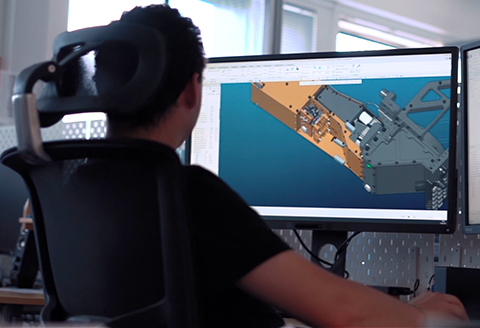

In addition to HUD development, we focus on the design, simulation and development of optomechanical systems for the defense industry. Our innovative approaches and technologies allow us to create tailor-made solutions for a wide range of applications, from ground military technologies to advanced aviation systems.

Another area of our activity is AI vision systems for industry. Our multi-purpose systems enable the monitoring and detection of various parameters and defects in industrial processes, which increases the effectiveness of measurements and production quality.

In addition, we cooperate on the development of new systems within the European Space Agency (ESA) and participate in the development of new telescopes. These activities combine our know-how in the field of optics and mechanics with the latest space technologies.

Our history dates back over 15 years, when we participated in the development of a number of scientific and R&D projects for synchrotrons and prestigious scientific institutions. Thanks to this, we have deep knowledge in the field of scientific optics and high-precision technological solutions.

We are constantly pushing the boundaries of what is possible in the field of optics, mechanics and AI technologies. We are proud that our systems contribute to the development of key industries and scientific discoveries on a global scale.

Team

From graduated optics specialists, through optics and automation designers, electrical engineers, PLC and VISION programmers, to electrical engineers.

Background

800 m² of production and laboratory environment in a modern facility in Prague, Horní Počernice.

Facilities

Certification

Laboratories

Establishment of Elya Solutions s.r.o. Originally the company focused on measuring instruments, fine mechanics and software development for research institutes.

Projects for research institutes, e.g. Paul Sherrer Institute, Austrian Insititute of Technology, DESY, ELI, Hilase, etc.

Major scientific projects for European synchrotrons.

The merger with LASCAM systems expanded the portfolio to include industrial automation.

Investing in equipment and expanding the team.

Elya Solutions s.r.o. started cooperation on space projects.

Our team has grown to 30 employees and we have delivered over 50 projects.