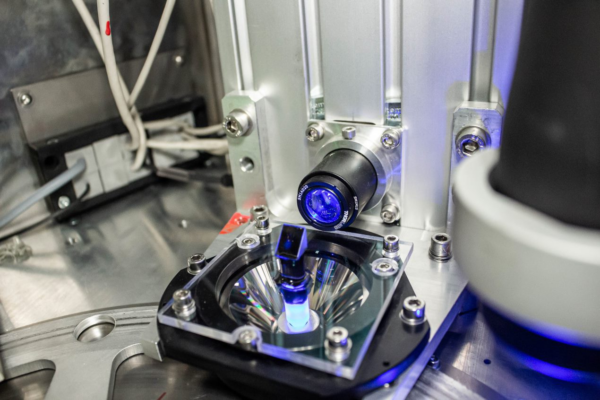

We are developers of advanced AI vision systems that use the latest machine learning, deep learning and neural network technologies.

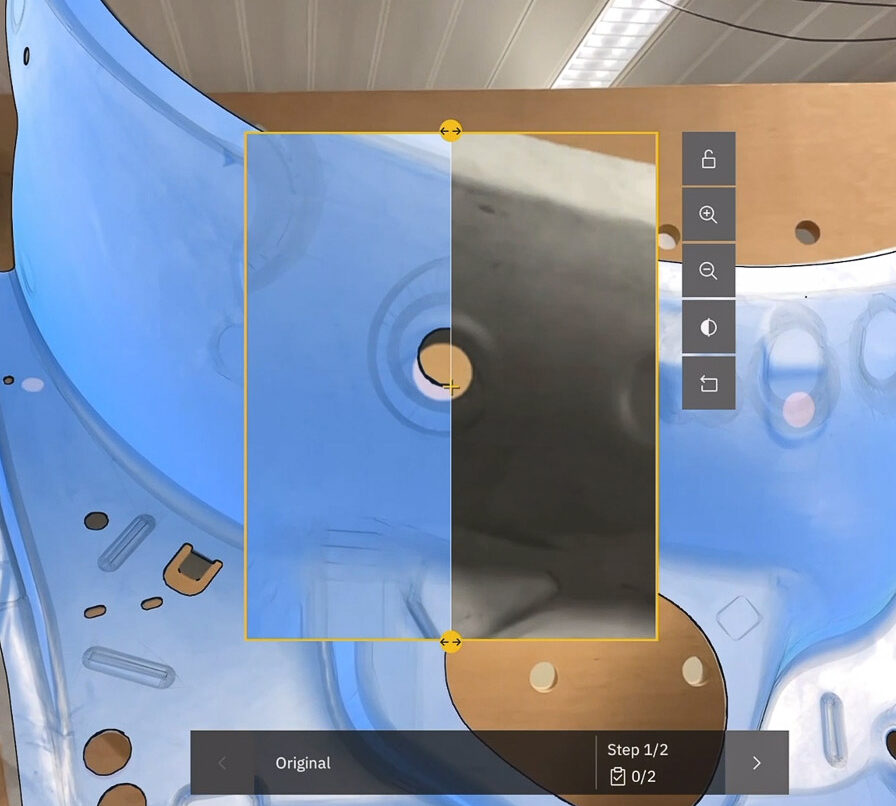

We design complete solutions from GUI interfaces for easy operation to optimized neural networks that ensure maximum accuracy and efficiency of control. Thanks to our technological background, we are able not only to design, develop and program the entire system, but also to manufacture a complete automated device or cell that is fully integrated into the customer’s production process.

Our AI systems are designed for industrial quality control, measurement, inspection, robot navigation and production monitoring. We use the latest 2D and 3D vision technologies, hyperspectral analysis and advanced algorithms for object detection and classification.