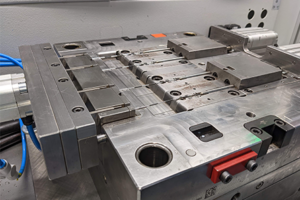

Implementation of a fully automatic multi-purpose cell providing laser marking followed by optical pattern quality inspection.

- Installation into a fully automatic line

- Laser marking of more than twenty patterns on multiple parts in one step

- Incorporation of more than 30 marking programs on two different types of automotive plastics

- Marking is followed by automatic optical inspection of the lasered marks and sorting of possible production rejects

- Data archiving for retrospective control of each product

Other Case Studies